All great inventors and visionaries from Albert Einstein to Thomas Edison, to Jeff Bezos, and Bill Gates have a story of how their discovery came to be. These stories are what made these people who they are. Our journey is no different. It has drastically shaped who we are, how we see things, and how our business looks today. We started with a cleaning agent that we used in nursing homes and ended up with the most revolutionary cleaning process for dental offices. Join us on our journey and see where we came from and where we are going!

Where it all Began

Originally, we started as a durable medical equipment (DME) company. To this day one of our divisions still sells, rents, and repairs mobility equipment. In our DME business, we dealt with many long-term care facilities. A major event happened in 2020 that shook the world, you might remember it. The COVID pandemic hit long-term care facilities and nursing homes particularly hard and sent them reeling for a solution to clean their facilities, protect their residents, and open the doors to the resident’s family members. This is when we stumbled upon a copolymer solution that would change our views of infection control.

The Infancy Stage

During this discovery time, we asked a lot of questions about what this copolymer solution could do, how long it would last, what makes it work, and the science behind it. This was a revolutionary product that was originally developed for the automotive industry, specifically for rental vehicles due to how many people were using them, and how much dirt and contamination was left behind.

Through this discovery phase, we learned the importance of the electrostatic sprayer. The electrostatic sprayer is what allowed the copolymer solution to get inside the air conditioning vents in the car, get in the seat cracks, and get in and around all the handles and control knobs in a vehicle.

Initial Implementation Phase

With this realization of the new generation of cleaning products with modern application methods, we brought this newfound knowledge to long-term care facilities. We spent months working on feasibility studies, logistical challenges, and pricing models to implement this cleaning process in long-term care facilities. We started to network with multiple facilities to start beta testing but ran into hurdle after hurdle to implement this into their facilities. This is the point that in one of our many team meetings, we wondered why we were focusing so much on long-term facilities, that we didn’t know much about, and had no connections into other than those we had formed through working with medical equipment.

The Adolescent Stage

This was the turning point in our discovery process. Our leadership team and investor group had many connections to the dental industry, not to mention that several members of the team were actually dentists. This gave us more insights into that industry, but we had to start some of the research all over again. We brought the copolymer solution and the electrostatic sprayers to the dental community and started to compare this process to other cleaning methods and companies out there. Everyone in the industry charged based on a price per square foot model and their service revolved around spraying as many square feet as possible. The problem with this method is that they overlooked the details of the dental environment. Through our experience with the dental market, we knew that the number of regulatory boards, and compliance offices that dentists must comply with is astonishing. They needed a solution that would comply with all departments, be quick and cost-effective, long-lasting and not interrupt their dental workflow.

Secondary Implementation Phase

At this point, we were spraying a solution in offices just like every other competitor, and we were getting asked the same question over and over. What makes us different, why is our product better, and how can we know that your solution is better and that it actually works? These were valid questions that we didn’t have answers for. Therefore, we went in search of a solution to these questions. One of our investors brought to our attention the science of luminometers, ATP testing, and microbial testing. They explained to us that this would allow us to verify if our product is cleaning like we claim and could also use the technology to check for “hot spots” in the office that were most likely to be contaminated. Some of this technology originally came from the food processing industry. We knew from our experience that doctors would like to know if they had microbial contamination in their office, so we added this to our process.

The Young Adult Stage

After the second implementation phase, we came out of it with the copolymer solution, electro-static spraying, ATP testing, and microbial testing. Now that we had all the foundational technology building blocks of our process, it was time to streamline the process to make it as conclusive and efficient as possible.

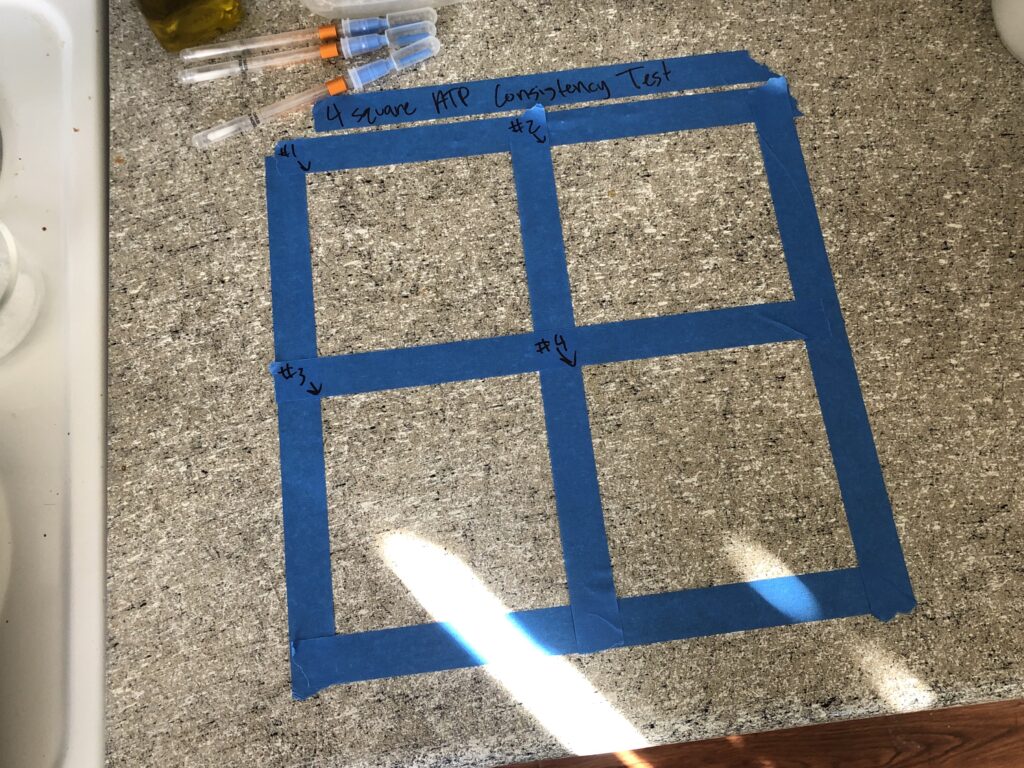

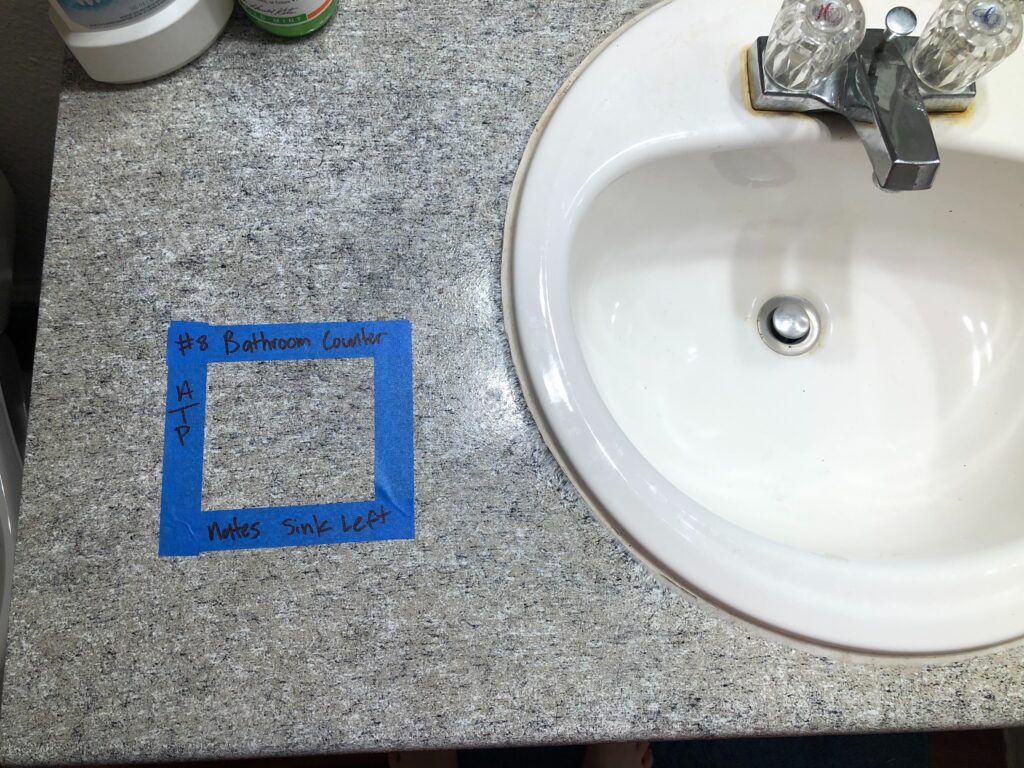

We needed to learn how to best apply the testing technology in our environment. We took hundreds of swabs everywhere from our office to our homes, and in our beta test offices. We started to get an understanding of how the swabs worked, developing protocols that would deliver long-term, reliable and consistent test results. We did exhaustive testing and learned about the many test variables like the importance of temperature controls, incubation times, transportation methods, and testing best practices.

Tertiary Implementation Phase

We now had our main product offering at this point and started to release the entire process into our beta offices. We were delighted when the tests came back the way we wanted in the actual environment we were developing this process. We had proof of concept and could start sharing this with the dental community. It has been received well, but like any disruptive technology, it requires some time to educate people on this new, paradigm-shifting approach to infection control in the dental offices.

Current Phase

This is where we find ourselves today. We are continuing to educate people while working on continuous improvements to make the process as seamless and easy for customers as possible. This includes improvements to scheduling, reporting features, travel, and service delivery improvements. It has been a long journey with a lot of learning and growth. What does the future hold? We don’t know, but we do believe that it is leading the healthcare market to a better infection control process.

Along with these continuous improvements, we are also working on additional R&D. The cleaning products we use have additional uses we are exploring, looking at additional items and ways of testing to have a more comprehensive view of the cleanliness of offices, and additional ways to get information to our customers and the public. These are exciting developments, and we can’t wait to see what the research uncovers.

If you would like to keep up to date on our newest discoveries, tips, and our improved process sign up for our weekly email list. As a thank you for signing up, you will get a free copy of our Investigative report, which shows the 12 dirtiest places in a dental office and gives you an idea of places you should pay special attention to.

MCS helps dental and healthcare facilities become safe places for patients and staff to work and seek medical and dental attention. We help our clients by not only providing long-term disinfecting and infection control protection solutions for their facilities but also by testing and verifying the cleanliness of those facilities. Every office we have been in has had some level of contamination, and our clients have seen a 100% decrease in microbial activity and an average decrease of 75% in their ATP levels. If you would like help in getting your office cleaner and safer, and have objective verifiable data to prove it, call us today at 469-778-7550 or contact us here.